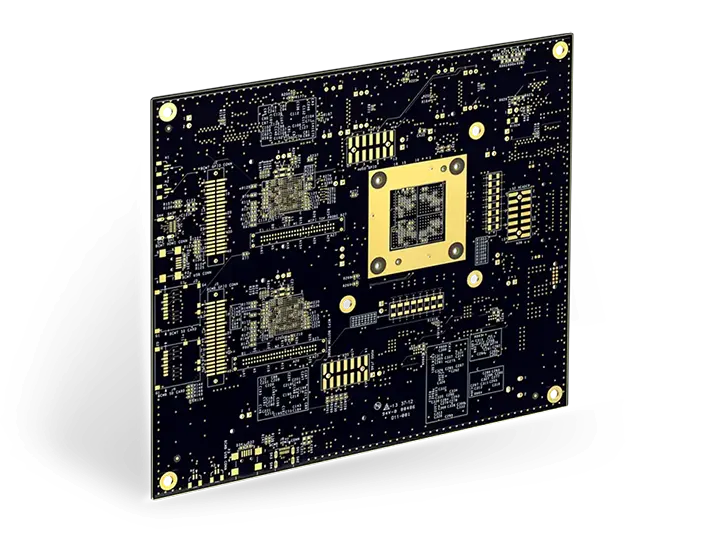

Multilayer PCB Fabrication

Get an instant online quote for manufacturing of Multilayer PCBs. SprintPCB provides flexible and transparent pricing for fast and easy ordering.

Instantly quote, rigid PCBs up to 30 layers

Ready to start building with the highest quality Multilayer PCBs?

SprintPCB engineers can help you efficiently manufacture your rigid Multilayer PCBs.

Feature | Technical specification |

|---|---|

Number of layers | 4 – 16 layers standard, 24 layers advanced, 30 layers prototype |

Technology highlights | Multiple layers of epoxy glass fiber bonded together with multiple layers of copper of varying thicknesses |

Materials | High performance FR4, halogen-free FR4, low loss and low Dk materials |

Copper weights (finished) | 0.5 OZ – 6 OZ |

Minimum track and gap | 0.075 mm / 0.075 mm |

PCB thickness | 0.40 mm – 7.0 mm |

Maxmimum dimensions | 580 mm x 650 mm |

Surface finishes available | HASL (SnPb), LF HASL (SnNiCu), OSP, ENIG, Immersion Tin, Immersion Silver, Electrolytic gold, Gold fingers |

Minimum mechanical drill | 0.15 mm |

Why SprintPCB can Provide the most

competitive PCBs

Under the long-term strategic cooperation agreement with laminate supplier , the price we get is 10% cheaper than most competitors

PCB Inner / outer layers fab with LDI equipment, the automatic production reduce our labor cost 5%

Lean manufacturing increases product yield

Multilayer PCB Manufacturer

Multilayer PCBs offer numerous advantages such as high assembly density and compact size. The shortened interconnections between electronic components lead to faster signal transmission and easier routing. Additionally, they provide excellent shielding effects. There is no limit to the number of layers in a multilayer PCB, with some designs exceeding 100 layers. However, the most common configurations are 4-layer PCBs and 6-layer PCBs.

When designing multilayer PCBs, it is crucial to maintain symmetry across layers, preferably using an even number of copper layers. Asymmetrical designs can cause warping.

Routing on multilayer boards follows the circuit's functionality, with more routing on the solder side and less on the component side, facilitating easier maintenance and troubleshooting. Power, ground, and signal layers should be separated to minimize interference among them. Adjacent layers' traces should intersect at right angles or run diagonally/curved rather than parallel to reduce inter-layer coupling and interference.

Compared to single-sided and double-sided boards, multilayer PCBs consist of several distinct layers, each serving a specific purpose:

Signal Layers:

These include the top layer, middle layers, and bottom layer, primarily used for placing components, routing, and soldering.

Internal Planes:

Also known as inner layers, these are dedicated to routing power and ground lines.

Mechanical Layers:

Used for board fabrication & assembly info: dimensions, datasheets, & via details.

Masks:

Including both top and bottom layers, these layers define non-copper areas for pads and other objects.

Silkscreen Layers:

Used for drawing component outlines, placing component numbers, and other textual information.

System Layers:

Display information about design rule violations.

As a premier multilayer PCB manufacturer, SprintPCB leverages advanced technology and meticulous processes to deliver high-performance PCBs. With their deep expertise, they ensure that every board meets stringent quality standards. This commitment to excellence makes SprintPCB a trusted partner in the electronics industry.

For those seeking a reliable multilayer PCB manufacturer, SprintPCB stands out with their comprehensive understanding of multilayer PCB structures and design principles. A well-designed multilayer PCB from SprintPCB not only enhances performance but also ensures durability and reliability in complex electronic applications.

About SprintPCB

We can provide competitive prices and guarantee the quality requirements of customers without excess quality. Our technical level can meet most of the industrial control and consumer products.

Manufacturing Equipment at SprintPCB

SprintPCB operate with most advance equipment in the industry to provide efficient production and high quality products with value added to our partners

Trusted by innovators since 2007

In the race to build tomorrow, SprintPCB engineers and PCB designers continually patent new technologies,

crossing design barriers—to help innovators bring new products to market.

"I am extremely satisfied with the quality of the PCBs you manufacture. The solder pads on each board are very smooth and the connections are very strong. I have worked with other manufacturers before, but the quality was always subpar. Since switching to SprintPCB, the quality of my projects has significantly improved. Thank you for your outstanding manufacturing process!"

- John Smith

Get High-Quality PCBs or PCBA at a Fraction of the Cost

Why Pay More for PCB Manufacturing?

Partner with Us for the Best Prices!

FAQ about Multilayer PCBs

A multilayer PCB is a printed circuit board that consists of multiple layers of conductive material sandwiched between insulating layers. This type of PCB is used for complex electronic circuits that require more space for routing and component placement.

A single-layer PCB only has one layer of conductive material, while a multilayer PCB has multiple layers of conductive material. The multiple layers in a multilayer PCB allow for more space for routing and component placement, making it possible to create more complex circuits.

Some of the benefits of using a multilayer PCB include increased circuit density, improved performance, reduced electromagnetic interference, and reduced circuit size.

The materials used in a multilayer PCB typically include a substrate material, conductive layers (such as copper), insulating layers (such as polyimide or FR4).

Multilayer PCBs are typically manufactured using a process that involves layering, drilling, etching, and laminating. The process starts with the creation of a substrate, followed by the deposition of conductive layers and insulating layers. The layers are then drilled to create vias and holes for component placement. Finally, the board is laminated to ensure stability and durability.

CONTACT US

We would love to respond to your queries and help you succeed.

During our business Hours: 9:00~18:00