PCBA manufacturer

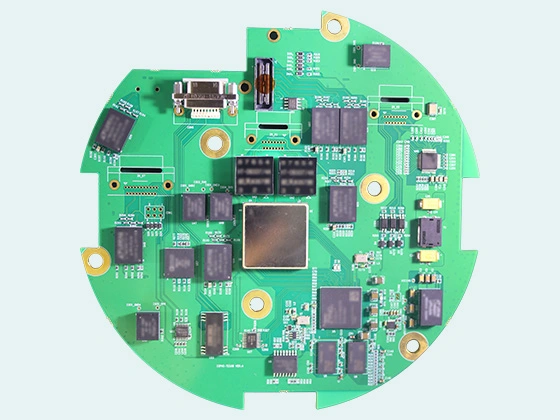

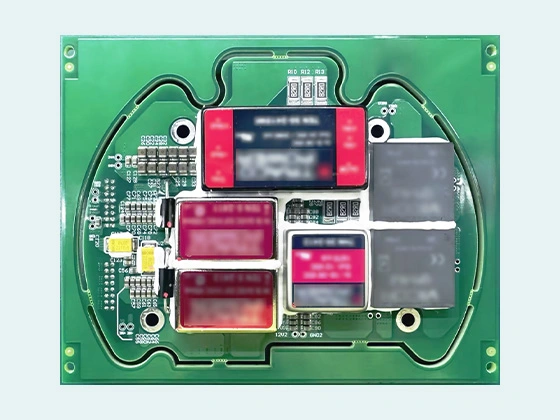

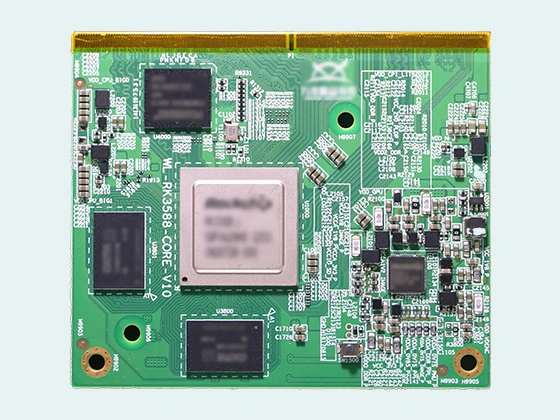

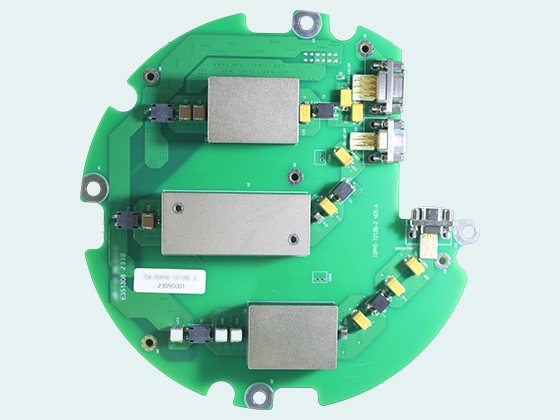

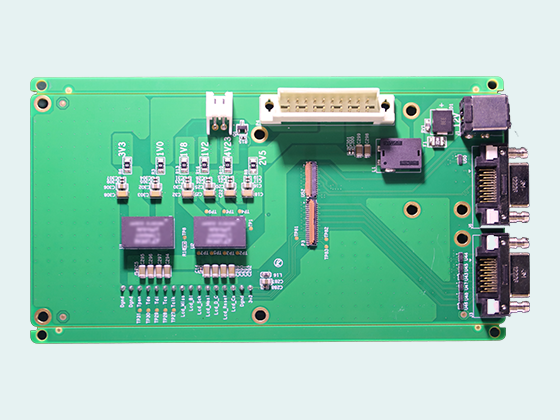

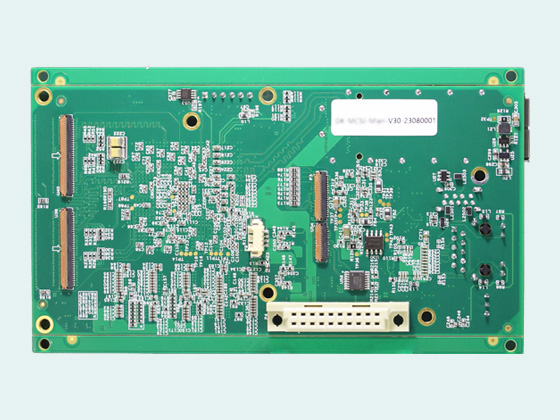

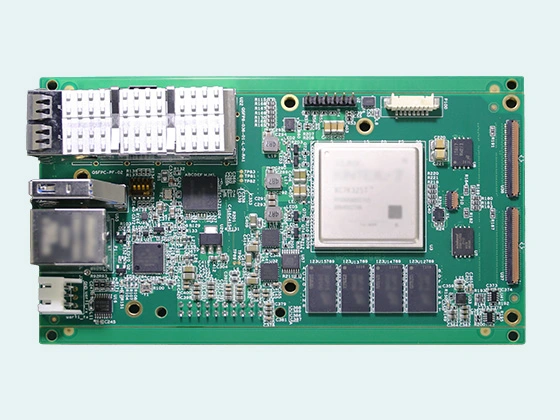

PCB assembly is the process of assembling all electronic components onto a printed circuit board.

PCBA Manufacturing Services

At our PCBA facility in Beijing, China, we specialize in comprehensive services that cover component sourcing, precision SMT, DIP, cable soldering and functional test.

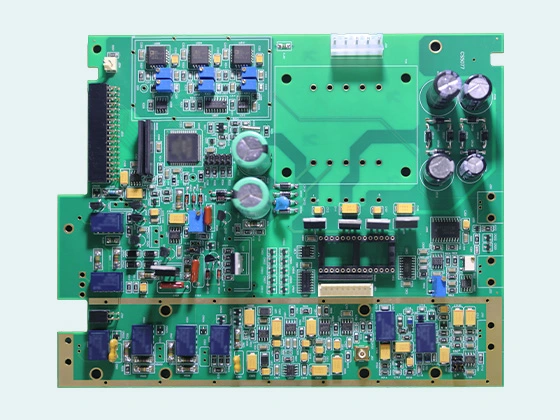

High precision SMT

2 sided SMT&THT assembly

Items | Conventional process | Unconventional processes | ||

|---|---|---|---|---|

PCB specifications for SMT | Length * Width | Maximum | L≤460mm | L>460mm |

W≤400mm | W>400mm | |||

Minimality | L≥50mm | L<50mm | ||

W≥30mm | W<30mm | |||

Thickness | Thickest | 4.5mm | >4.5mm | |

The thinnest | 0.5mm | <0.5mm | ||

Components for SMT | Dimensions | Component thickness | ≤6.5mm | 6.5mm<T≤15mm |

Maximum size | 200*125mm | >200*125mm | ||

Minimum specs | 0201 | 01005 | ||

0.6*0.3mm | 0.3*0.2mm | |||

QFP, SOP, SOJ and other multi-pin components | Minimum PIN spacing | 0.4mm | 0.3≤Pitch<0.4mm | |

CSP、BGA | Minimum ball spacing | 0.5mm | 0.3≤Pitch<0.5mm | |

SprintPCB's PCBA division currently operates in a facility covering 5000 square meters with about 300 employees. It specializes in manufacturing of prototype small batches to large-scale PCBA for non-consumer electronic industries such as security, communication base stations, industrial control, automotive electronics, medical, etc.

We provide comprehensive services including precise circuit board surface-mounting, soldering, product testing, aging, packaging, shipping, chip programming and burning, connector crimping, plastic casing ultrasonic welding, laser marking, engraving, and BGA rework. Our production facilities feature state-of-the-art equipment, including Fuji, Panasonic, and Yamaha surface-mounting machines, Jintuo leaded/lead-free 10-zone reflow ovens, leaded/lead-free wave soldering machines, as well as fully automated PCBA cleaning machines and X-RAY, AOI, and BGA rework equipment. Our complete hardware and software capabilities allow us to meet a wide range of customized customer needs.

Items | Sample small batches | Batch | ||||

|---|---|---|---|---|---|---|

Quantity | ≤100 pieces | 101--1K pieces | >1K pieces | 1K--3K pieces | 3K--10K pieces | >10K pieces |

Lead time | 24--48H | 48--72H | Delivery starts from 3th day, and can be shipped in batches | 48--72H | 72--96H | Delivery starts from 3th day, and can be shipped in batches |

Comment | 100% products delivery pass rate (for non-functional test products) | Products delivery pass rate≥ 99% (for non-functional test products) | 99% products delivery pass rate | |||

The delivery time of the products will be calculated after the EQ and materials are confirmed | ||||||

Get High-Quality PCBs or PCBA at a Fraction of the Cost

Why Pay More for PCB Manufacturing?

Partner with Us for the Best Prices!

PCBA processing process

About SprintPCB

We can provide competitive prices and guarantee the quality requirements of customers without excess quality. Our technical level can meet most of the industrial control and consumer products.

CONTACT US

We would love to respond to your queries and help you succeed.

During our business Hours: 9:00~18:00